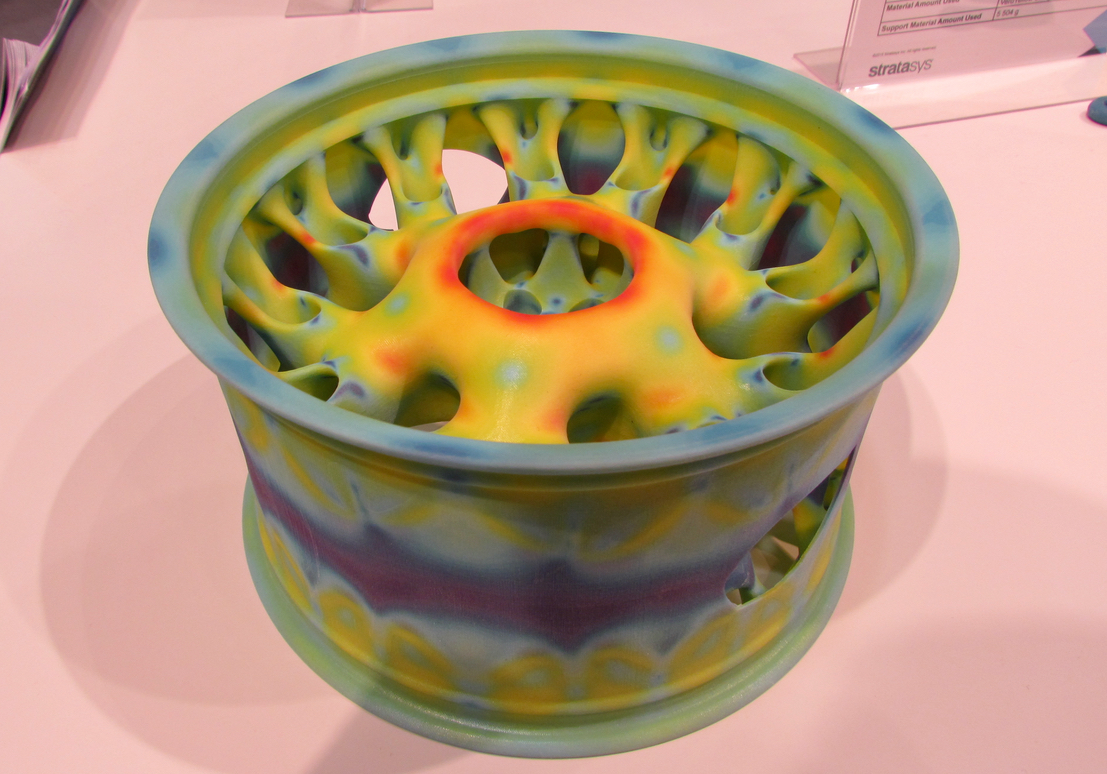

Stratasys has produced a very interesting visualization using their color 3D printing processes.

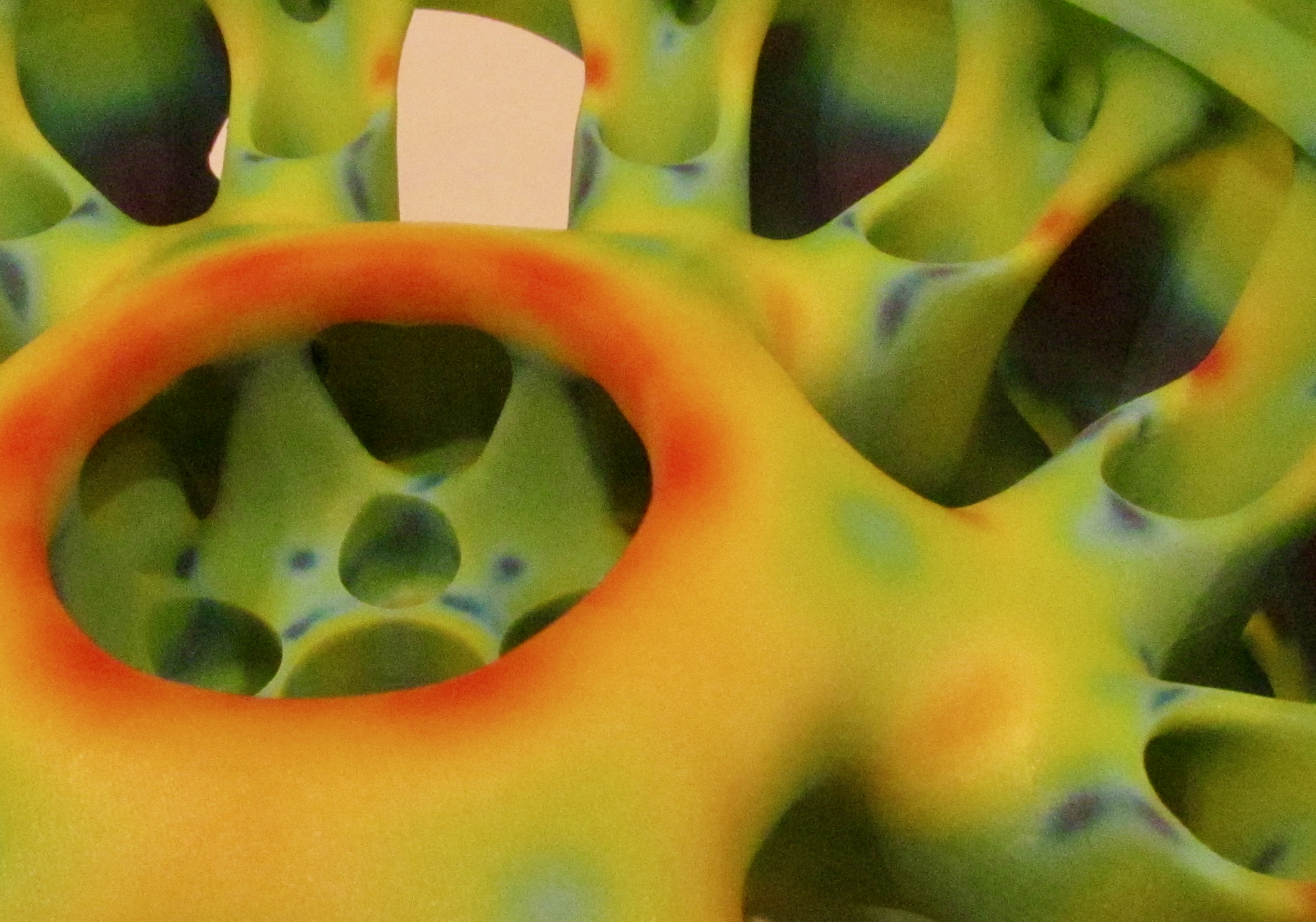

The image above is of a wheel rim, as you might recognize, but it’s covered with a seemingly wild color pattern.

That’s because they’ve purposely done so, as the color pattern is actually very useful. It represents the physical stress analysis of this part.

Stratasys explains in a bit more detail:

Finite Element Analysis (FEA) is a computer-based method of analyzing and simulating the behavior of components under a variety of conditions, including force, temperature, vibration and motion. FEA calculates displacements, strains, and stresses under internal and external loads. These predictions confirm if a design is suitable or if modifications are required to prevent failure. To bring FEA results into the real world, PolyJet 3D printers create physical models that retain FEA color mapping. Rather than interpreting results from a computer screen, designers and engineers can visualize the analysis with models that are hand-held.

This particular example was produced on an Objet Connex3 (a three-color 3D printer) in about 100 hours, using over 5kg in material.

I’ve seen many color prototypes produced, but virtually all of them are done for testing the visual appearance of a product. Does the color pattern show properly? Does it complement the physical design effectively? But this is something entirely different: color being used for analysis.

I expect that this type of “non visual testing” use of color 3D printing could be used in a variety of ways.