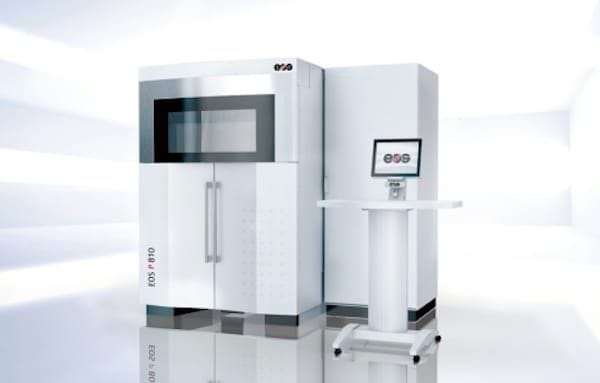

EOS is one of the largest industrial 3D printer manufacturers in the world, and they soon will have another product in their portfolio.

They pre-announced the new EOS P 810, a polymer machine. EOS makes two types of machines: those that print polymers and those that print metals. It’s easy to distinguish the two among their products as the polymer machines are “P” and the metal machines “M”. The EOS P 810 is a polymer machine.

It’s very similar to their previous P 800 3D printer, a device that proved quite popular in industry. However, there are some notable differences:

The build volume on the P 810 is actually a bit smaller than the P 800. While their XY size is the same at 700 x 380mm, the Z axis on the P 810 is only 380mm, whereas it is 560mm on the P 800.

Both machines sport dual lasers for rapid simultaneous 3D printing, but the P 810’s lasers are 70W, while the P 800’s are less at 50W.

But those are minor compared to the big change: the P 810 is able to 3D print EOS’s new industrial material, HT-23.

This unusual material is a form of PEKK, and offers tremendous engineering properties. It’s very strong, partly due to the inclusion of carbon fiber particles within the material.

While there are now several 3D printers on the market that are able to 3D print PEKK-type material, EOS’s HT-23 is different in that it holds several very important certifications.

EOS explains that HT-23 is not only flame and UV resistant, but also meets or exceeds the aerospace FAR 25.853 standard as well as the EN 45545 standard for the mobility industry. They say:

HT-23 is the first carbon fiber-reinforced PEKK material that can be processed on EOS systems, as such offering isotropic part properties. Parts additively manufactured with this material offer high strength, low weight and are capable of withstanding high temperatures. It is the first high-performance material with a low refresh rate of 40 percent, as such also contributing substantially to reduced costs-per-part.

(The refresh rate they mention refers to the percentage of “fresh” powder required on each print job, since some unused powder on previous runs can be reused.)

These certifications and others they will likely obtain for this material are key to future sales. Consider the case of a manufacturer building certain parts for those industries. It’s very likely they cannot sell any products to their clients unless the parts pass a number of certifications.

If such an operation were presented with a system option that did not include certified material and a machine able to print it in a certified manner, they would reject that option outright. It would not work for them.

On the other hand, a machine and material combination that did include the ability to meet the regulations would certainly be considered, if not welcomed.

In other words, no certification, no sales, in many cases. That’s the market EOS is pursuing with the P 810 3D printer, which appears to be specifically designed to print HT-23 and similar materials.

However, this machine is not quite ready for sale yet. EOS explains they will be showing off the machine at this year’s FormNext event in November, where we will certainly take a close look.

Via EOS