I’m looking at a new crowdfunding 3D printer launch.

Yes, I know what you’re thinking. You are thinking that there are far too many Kickstarter launches of questionable, underpriced and overpromised 3D printers just waiting for catastrophe and that this is probably just another one.

It may indeed be so, but after looking at the specifications of the new machine by the eponymously named Venturi 3D machine, it could have some merit.

It’s a sub-USD$1000 3D printer, which puts it into the area of suspicion: many previous 3D printer launches have set their price far below what would be required to successfully deliver the device, let alone maintain a properly operating company afterwards.

That may not be the case with the Venturi 3D, as they’ve priced it starting at USD$749. This is a price point far above the USD$200 “death level” below which companies tend to fail due to underpricing. That’s good.

But what about the technical bits of this machine?

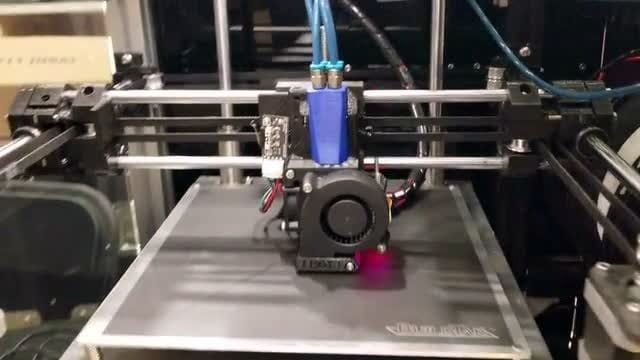

It’s a reasonably-sized machine with a healthy build volume of 220 x 220 x 220mm, and can optionally handle up to four extruders. However, there’s only one nozzle, so the extruders can mix filaments on the fly. This multi-material approach also eliminates the possibility of misaligned hot end nozzles, as there is only one!

By the way, the nozzle can hit 300C, which is more than sufficient for using the most common engineering materials such as Nylon. The print surface can be as high as 100C, making it suitable for warpy materials like ABS.

One aspect that the company seems to have taken special attention to is heat control. They have built an enclosure around the mechanism, unlike many other larger-sized low cost desktop 3D printers. The enclosure permits the passive capture of stray heat from the nozzle and build plate, raising the ambient heat around the print itself. This should increase print quality and reliability.

But there’s another heating aspect that few other machines incorporate: Venturi 3D has mounted the filament spools INSIDE the enclosure. While this may be a bit more inconvenient for loading and unloading spools, it does provide a means to pre-heat the material before and during printing. Pre-heated spools tend to perform slightly better as they require less heat to move the material temperature to operating range.

The enclosure also sports a locking mechanism that might be useful in certain operating conditions, such as schools or public offices.

Curiously, the machine uses a Bowden extruder even though the material is “close by” inside the machine. I might have thought they’d use a direct extruder. (Not sure of the difference? Read this.) Perhaps it’s to permit the space required to accommodate four extruder motors on multimaterial machines.

Aside from the heating features, the Venturi 3D includes a number of becoming-standard features, such as automated leveling, BuildTak print surface, 0.05mm minimum layer size, BondTech extruder gearing, Olsson ruby nozzle, E3D V6 hot end, and a 7” color touch screen, implemented with an actual Android tablet.

The machine is available in several configurations starting at USD$749 for a single material, and USD$849 for a dual version.

Is this machine for you? It seems to have many excellent technical characteristics, but there is always the question of startup viability. You may wish to review our crowdfunding checklist before you engage with this venture.

The company has set an ambitious goal of USD$180,000, which is to be met by campaign close in early September. As of this writing they’ve sold over 40 units and have raised near USD$12,000. This means they’ve have to sell something like 200+ machines in the remaining days, or about 7-8 units per day, in order to meet their goal.

We wish them well!

Via Kickstarter