A new Kickstarter project offers a means of 3D printing in multiple colors.

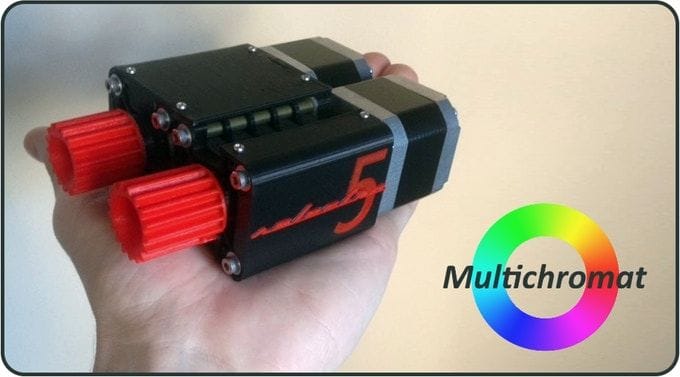

Protea Design hopes to attract buyers to its new Selectra system that enables a common filament-based 3D printer to accept up to five different filaments at the same time, without significant modification to the original 3D printer.

There have been several attempts at this concept done before by others, but almost all have found it to be problematic. Will Protea Design succeed? It seems they have a very different technical approach that may indeed work.

Most multi-filament systems simply strap several normal extruders together and hope to coordinate feeding them into a single nozzle through a system of tubes. This approach has proven quite expensive, as in the case of a five-filament system, you’d literally need to pay for five full extruder systems!

Protea Design’s approach is to use an ingenious combination of only TWO stepper motors to power all five filament drives.

One motor is used to push the active filament; the other mother is used to “select” which filament is to be active through a system of mechanical cams. They’ve wrapped this tech up in a small attachment box that looks like this in operation:

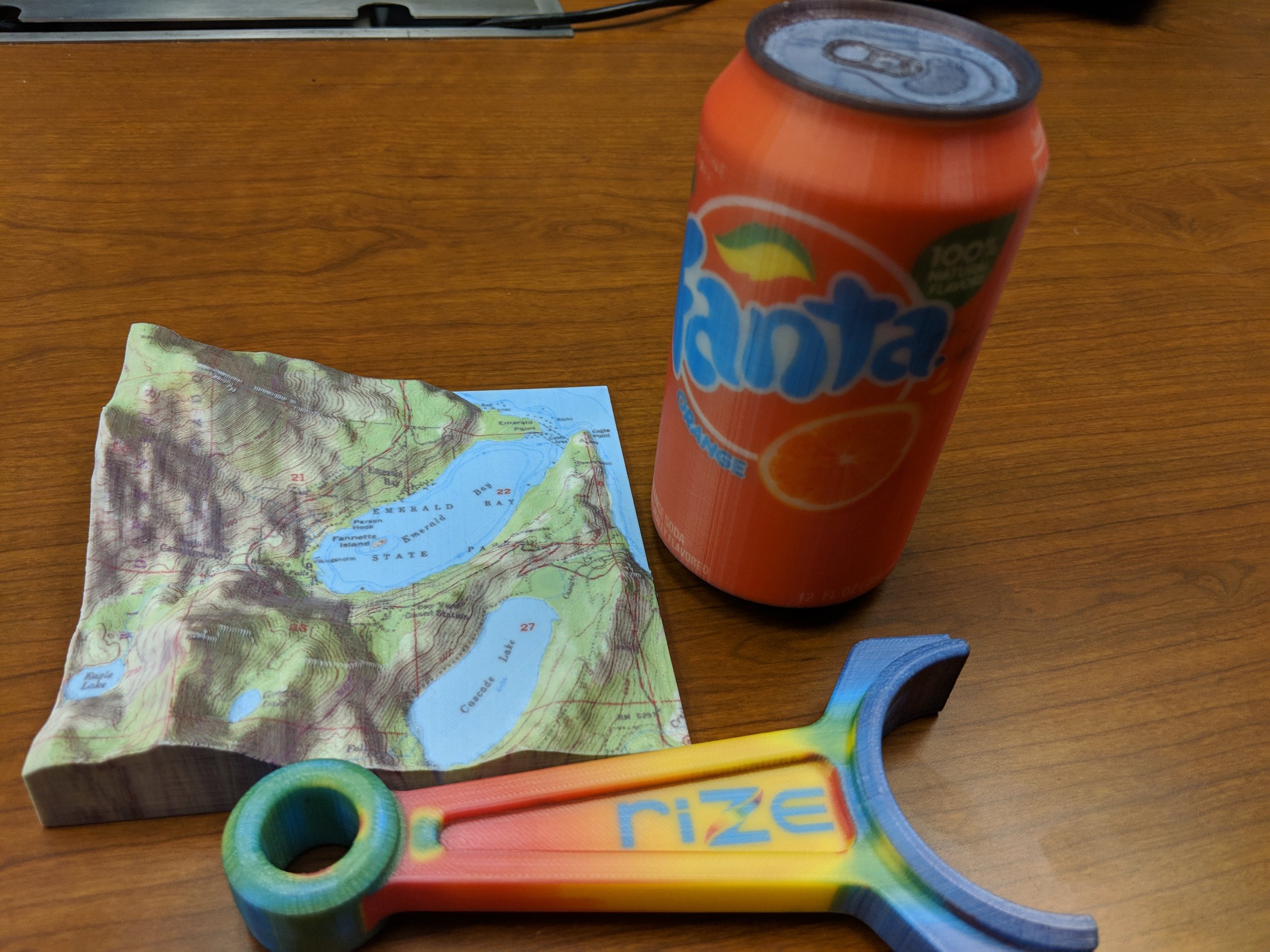

As you can see in the concept diagram, only one filament can be in the hot end at a time, meaning this product can only 3D print “solid” colors and cannot mix them as some competing systems can achieve.

![The Selectra multi-material concept [Source: Protea Design]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a729deeb9.jpg)

The diagram also suggests that the typical installation of the Selectra would be on Bowden-style filament 3D printers, because the motor doing the pushing is far away from the hot end. That’s precisely what the Selectra is doing, so a Bowden hot end expecting to receive filament would simply continue to do so.

What happens if you have a direct drive 3D printer instead of a Bowden system? Protea Direct says that this is also possible:

“Selectra has also been tested with direct drive extrusion systems. Although a more advanced retrofit, this case sees Selectra feed the hotend mounted stepper its required material. An excellent solution for ultra-mega-flexible materials.

Functionality relies on either a second separate extruder stepper driver port on your 3d printer’s control board OR an electronic switch expansion. You are able to use Selectra if one of the above requirements are met.”

Wait, “retrofit”? What does one have to do to install one of these devices?

It turns out that it requires both power and control signals from your 3D printer. This means you will have to open up your controller board enclosure and attach the required wiring to the appropriate points on the controller board. Protea Direct says that almost all 3D printers will have the right ports free for use, so it should be simply a matter of attaching cables.

One challenging aspect of this design will surely be the constant long retractions. Consider what happens when the filament color is to change in mid-print. First, the current filament must be pulled all the way back past the “splitter block”. Then the new filament must be pushed through the splitter block all the way down to the hot end. In the video above you can see the Selectra’s motors spinning significantly, presumably to accomplish all this pulling and pushing.

My concern is how this will play out on the filament, as stripped filaments is a frequent cause of print failure. The Selectra concept requires a lot more “mileage” to be placed on filaments and thus could increase this possibility. But we’ll soon see if this happens or not.

![Example of multi-material 3D print by Selectra [Source: Protea Design]](https://fabbaloo.com/wp-content/uploads/2020/05/selectra-result_result_img_5eb0a72a29810.jpg)

The Selectra system is available on Kickstarter now for a few more days, and it seems they’ve already reached their funding goals, increasing the possibility they may produce the unit. The price of the Selectra is approximately USD$125, which is not too bad.

One thing to note, however, is that this is a crowdfunding launch, and they have a higher probability of failure than obtaining equipment from conventional sources. We recommend you have a read through our crowdfunding checklist to gain some assurances that this project is for you.

One more thing: it turns out that Japan-based Protea Design has previously offered one product, a kind of filament production system called the “DNA Extruder”. Evidently this project was not successful, apparently due to an insufficient amount of funds being raised during their campaign. That part, at least, will be different for this campaign.

Via Kickstarter and Protea Design