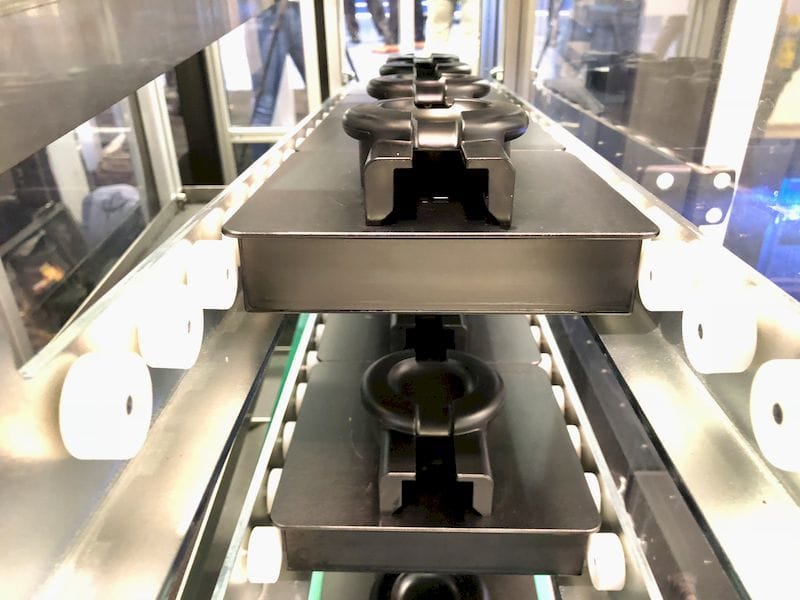

![3D print plates ready to roll inside a Formlabs Form Cell unit [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/formlabscellhoppersplates-1_result_img_5eb0a51f53e66.jpg)

Formlabs announced the installation of one of their new Form Cell systems at a health care provider, demonstrating the viability of their strategy.

The company has long been producing standalone resin-based 3D printers, culminating with their most recent and popular model, the Form 2. These machines have proven to be extremely easy to use and provide excellent output.

But is Formlabs content to simply sell many of these excellent machines? It appears they want to do more with this technology, and for that they developed the Form Cell.

This is a kind of robotic “accessory” for the Form 2 desktop 3D printer in which many manual operations are automated. The Form Cell creates an assembly line-like mechanism, where 3D prints are produced, cleaned and cured automatically. This enables more rapid production of parts.

The Form Cell appears to be technologically complete system, aside from support removal and any desired finishing required, such as painting. Much manual labor is removed. But is this enough to justify the purchase of a Form Cell?

It seems to me that one could justify the purchase of a Form Cell only if there is a sufficient and continuous volume of 3D print work expected. If one were to have several Form 2s in operation continuously, an operator would be kept busy looking after each machine and its output. Depending on the specifics, there would be a break-even point where the acquisition of a Form Cell would make sense. This would vary by situation, but be assured that it would likely require a very healthy volume of prints.

Knowing that, we now see that Formlabs has announced the installation of one of their first Form Cell units, located at Northwell Health, “New York State’s largest health care provider with 23 hospitals”.

While we normally are not so interested in specific machine installations, there are a couple of noteworthy things with this instance.

First, the installation is obviously a milestone for Formlabs, who I am certain are highly engaged in selling the concept to multiple prospects. With one installation completed it becomes far easier to sell the idea to further clients.

Secondly, it validates Formlabs’ strategy of moving towards production 3D printing. Standalone 3D printers are typically used for prototyping, and the occasional very low-volume production run. That’s harder to do because of the manual nature of the Form 2 and its relatively low resin capacity. But one client buying a Form Cell indicates that it is indeed possible for Formlabs to enter the production game.

Finally, the fact that Northwell Health bought this system indicates that they have in fact a sufficient volume of work required to justify the purchase. What exactly might that be?

Formlabs explains that Northwell Health’s ”state-of-the-art 3D printing facility” will produce patient-specific anatomical models. These are used for planning complex surgeries through physical familiarity with the geometry of the operation site and also to assist in explaining the procedures to the patient.

That last use case is one I hadn’t seen before. Previously my understanding was that medical professionals would use the 3D prints to study their approach for specific procedures, as they would 3D print a portion of the patient’s anatomy. But I hadn’t heard they were showing them to the patients. Patient Barnaby Goberdhan explains how this worked in a case involving his son Isaiah:

“Having a 3D printed depiction of my son was really helpful when talking with the doctor about his surgery. The doctor was able to do more than talk me through what they were going to do – Dr. Patel showed me. There is almost nothing more frightening and stressful than having your child go through surgery. There were several options Dr. Patel walked us through for the best way to preserve Isaiah’s teeth and prevent additional cuts within his mouth. I wanted all of my questions answered so I could be less fearful and more prepared to talk my son through what he was about to face. I wanted Isaiah to feel prepared. With the 3D model, we both felt more at ease.”

I now see what’s happening here: for at least some medical procedures, this organization seems to be routinely 3D printing anatomical models for both their professionals and patients to gain benefit.

That sounds a lot like a low-volume custom production line to me. With 23 hospitals in operation, it would appear they have sufficient volume to justify this production. Now we have another production use case for 3D printing.

Via Formlabs

FELIXprinters has released a new bioprinter, the FELIX BIOprinter, which is quite a change for the long-time 3D printer manufacturer.