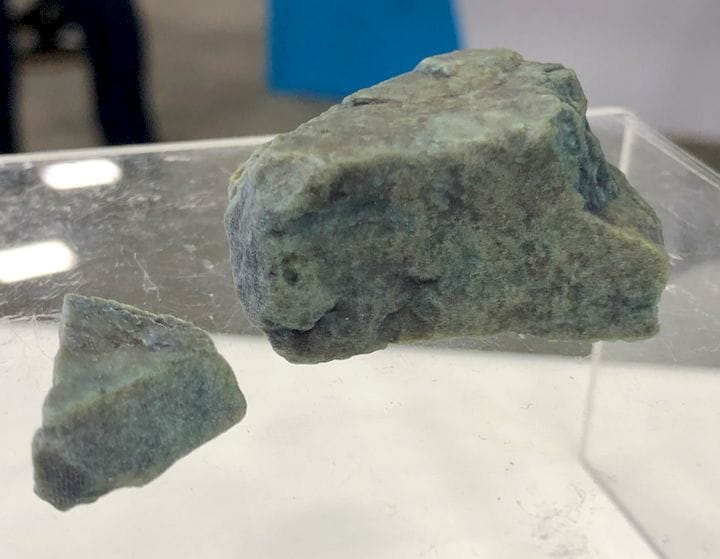

![The winner of a full color 3D printing design challenge - a rock! [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09c0394925.jpg)

Color 3D printing has never really taken off, but there may be a good reason why.

3D printing technology has been around for decades, and for most of that time it has been extensively used for prototyping. More recently there have been some moves into full end-use production, but that’s still a minor part of the use of the technology.

Virtually all of that 3D printing activity has been in mono-color objects, as the equipment and software has largely been focused on that mode of printing.

However, there have been a few methods of 3D printing in full color — and by full color I don’t mean “spot” color by swapping a material or three during printing — I mean full, RGB textures of potentially photographic quality. In fact, we recently made a list of the current vendors of full color 3D printers.

There’s only a dozen or so full color 3D printers, whereas there are literally hundreds of, perhaps even a thousand, mono-color 3D printers on the market today.

Why is this? I think we saw some evidence that hints at one possible reason for the situation.

Our evidence is from a recent design contest, where Stratasys’ GrabCAD operation held a challenge focused on realistic color 3D printing. They were trying to show the full capabilities of their powerful J750 full color 3D printer. This machine produces among the most vibrant colors possible on any current color 3D printer, as you can see in this amazing 3D print:

![An amazing full color “visible” hand 3D printed on a Stratasys J750, and a 3D printed rock [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09c0405dda.jpg)

GrabCAD received a number of entries for this challenge, and our own Sarah Goehrke was one of the judges of the event, which displayed the leading entries physically 3D printed on the J750 and shown off at the recent SOLIDWORKS World 2019 event.

![Make it Real judges with some of the 3D printed entries (L-R): Pat Carey, SVP Americas, Stratasys; Gina Scala, Director of Global Education, Stratasys; Sarah Goehrke, Managing Editor, Fabbaloo [Image: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/mirjudges_img_5eb09c04690f7.jpg)

The most popular item was actually a rock. Yes, that one shown at top. I saw this print in person, and yes, it was quite realistic. But what entries did it beat out?

Well, there was this one:

![A full color kidney 3D print made on a Stratasys J750 [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09c04d0497.jpg)

And this one:

![A color 3D printed toothbrush, made on a Stratasys J750. The bristles are rigid, not soft, though the J750 can print with flexible materials [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09c0524aca.jpg)

And this one:

![A 3D printed medical cast made on the Stratasys J750 [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09c057a98c.jpg)

There’s something noticeable about these entries: they don’t truly exploit the full color capabilities of the machine. They are “color” and have some textures on their surfaces, but they really don’t stand out. A rock won the contest, for goodness sakes.

We’re told that among the not-selected entries, there were some more intriguing 3D models, but they were not actually printable for one reason or another. The rules of the contest did not permit GrabCAD or Stratasys experts to “fix” them, so they didn’t make it to the final judging.

What does this tell us about the state of design for full color 3D printing?

I think it shows there is a significant gap in understanding of how to actually use full color 3D printing. The printable models entered in the GrabCAD contest were rudimentary, perhaps made by those most familiar with mono-color 3D modeling. The unprintable 3D models submitted could have been made by color 3D artists unfamiliar with 3D printing constraints as their typical output is used for visual applications only.

With the huge current interest in VR, gaming and 3D interfaces, I suspect most of the educational direction for 3D artists does not focus on design for 3D printing.

It may be that full color 3D printing does not grow significantly until we see a change in the educational focus in 3D design. There are some things that color 3D printer manufacturers could do.

I believe it may be possible for manufacturers to intervene in the educational world by introducing incentives, equipment, software and services that could attract the attention of students and educators. Perhaps it may be that a consortium of full color 3D printer manufacturers could offer scholarships or other incentives to institutions to help them crank out designers with exposure to full color 3D printing.

Via GrabCAD

If you’re a youngin’ whose neurons have just myelinated or an educator who’s responsible for bludgeoning their brain tissue with knowledge, there’s a 3D printer option you’ll want to add to your lab list – A RIZE 3D Printer.