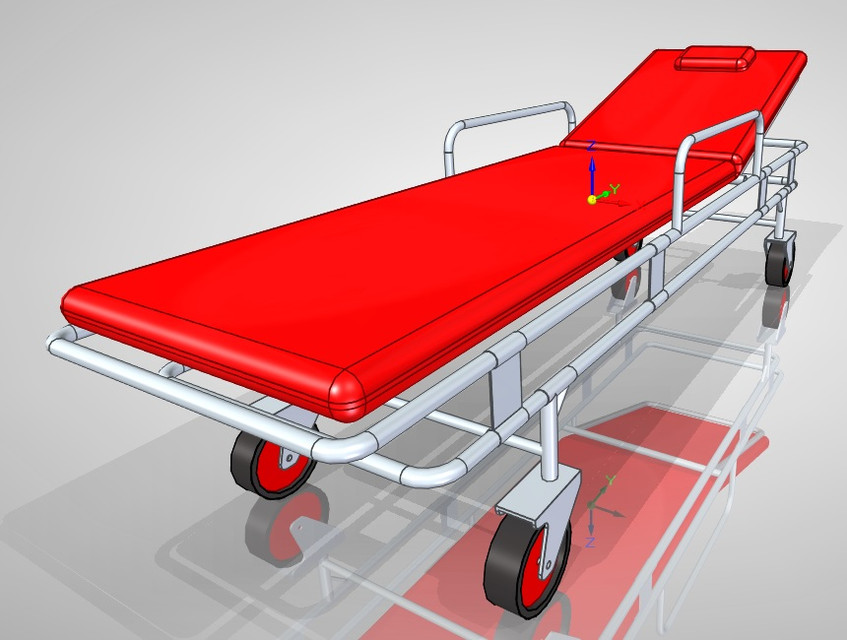

![3D Printed Ambulance Stretcher [Source: Hamilton Triana via GrabCAD ]](https://fabbaloo.com/wp-content/uploads/2020/05/Ambulance1_img_5eb097f19f8d4.png)

Charles Goulding & Preeti Sulibhavi of R&D Tax Savers examine 3D printing usage in emergency medical services.

The first hospital-based ambulance service began in 1865 in the United States. It started at the Commercial Hospital in Cincinnati, Ohio; Bellevue Hospital in New York City started an ambulance service thereafter in 1869. Edward Dalton, former Union Army surgeon, directed the Bellevue Hospital ambulance service. He believed that speed was king.

In saving people from debilitating injuries, Emergency Medical Technicians (EMTs) should not incur injuries themselves. If the injuries associated with handling Emergency Medical Services (EMS) stretchers does not kill EMTs, then the irony certainly would.

Considerable research and development has been conducted in regards to reconditioning, refitting and generally improving the structure of EMS stretchers and patient transport fleets. The extensive research and development involved in improving EMS stretchers and cots has helped in reducing injuries incurred by EMTs and other EMS workers.

In addition to reducing the injuries incurred by EMTs and other EMS workers, ambulance stretcher and cot technological improvements have also vastly helped save countless lives during a period of time when patients are exceedingly susceptible and vulnerable. One of the key leaders in this industry is Stryker. Not only does Stryker have numerous patents to its name, the most recent being that for a sterilizable enclosure for securing portable electronic devices, but it also carries out its innovative ideas utilizing effective manufacturing methods.

Ambulances and Fire Trucks: On the Scene

Often, when an ambulance is seen rushing to a formidable scene it is accompanied by a fire truck. There are several reasons for this. Ensuring that enough staff is available to take care of the patient is critical and fire trucks carry the same advanced life support equipment as ambulances. And people on fire trucks/engines are also trained as paramedics and can assist under adverse health circumstances and can begin care before the arrival of an ambulance. Fire trucks are usually not as busy as ambulances and can be just minutes away from any given emergency.

There are a myriad of recent technologies that have vastly improved health outcomes in emergency situations. In 2005, a revised document co-published by the three leading emergency medical services organizations (The American College of Emergency Physicians, The National Association of EMS Physicians, and The American College of Surgeons) included a list of resources needed on ambulances for appropriate homeland security and to optimize pre-hospital delivery of care. The equipment required is divided into that used for basic life support (BLS) and that used for advanced life support (ALS). Equipment required for BLS includes oxygen administration equipment and automated external defibrillators (AEDs). For ALS, equipment includes medications and pre-loaded syringes as well as airway and ventilation equipment.

3D Printing to the Rescue: Customizable Subsystems

With the requirements for tremendous amounts of subsystems that must be integrated into a fixed space, obviously there will be numerous specialized companies that require detailed custom design work. This presents an excellent opportunity for 3D printing to accommodate the intricate designs and framework requirements.

![LED Compartment Light [Source: Federal Signal ]](https://fabbaloo.com/wp-content/uploads/2020/05/Ambulance2_img_5eb097f24116e.png)

Fire trucks require sirens and speakers. There are several categories that differentiate between form and function. Exterior mount and perimeter warning lights are also necessary as well as directional signals. 3D printing can be a useful tool to create these customizable parts for life-saving missions. Compartment and dome lighting are also requirements as well. In fact, 3D printed LED lighting might offer the perfect solution.

Federal Signal and Tomar are highly specialized companies that provide emergency services with necessary equipment to perform lifesaving procedures. Federal Signal and Tomar seek to find innovative products and solutions to keep emergency services workers, first responders and communities safer and more secure. This is where 3D printing can be of assistance. With flexibility in design and durable construction, 3D printing and additive manufacturing are the solutions that these problem-solvers are seeking. 3D printing offers a greater range for design and construction as well as increased accuracy and precision.

![VPX Signal Master [Source: Federal Signal ]](https://fabbaloo.com/wp-content/uploads/2020/05/Ambulance3_img_5eb097f28c902.png)

The Research & Development Tax Credit

Enacted in 1981, the now permanent Federal Research and Development (R&D) Tax Credit allows a credit that typically ranges from 4%-7% of eligible spending for new and improved products and processes. Qualified research must meet the following four criteria:

-

Must be technological in nature

-

Must be a component of the taxpayer’s business

-

Must represent R&D in the experimental sense and generally includes all such costs related to the development or improvement of a product or process

-

Must eliminate uncertainty through a process of experimentation that considers one or more alternatives

Eligible costs include U.S. employee wages, cost of supplies consumed in the R&D process, cost of pre-production testing, U.S. contract research expenses, and certain costs associated with developing a patent.

On December 18, 2015, President Obama signed the PATH Act, making the R&D Tax Credit permanent. Beginning in 2016, the R&D credit has been used to offset Alternative Minimum Tax (AMT) for companies with revenue below $50MM and now, startup businesses can obtain up to $250,000 per year in payroll tax cash rebates.

Saved by 3D Printing…

Working with emergency services teams, these highly specialized EMS equipment companies have helped to improve health outcomes under the most adverse circumstances. In developing technologies to improve health outcomes, it is critical to understand the needs of patients, as well as the needs of EMTs. 3D printing offers a unique solution to meeting the demands of both segments with higher-quality products and hopefully better outcomes.

Healthcare 3D printing attempts to solve two problems that plague providing care: customization and cost.