![DICOM from MRI scan of a liver imported into Simpleware [Source: 3D LifePrints ]](https://fabbaloo.com/wp-content/uploads/2020/05/lifeprints_02a_img_5eb094cd225a1.jpg)

Medical 3D printing is becoming increasingly valuable for manufacturers and clinicians to solve patient-specific problems through tailored implants to improve diagnostic decision-making.

Creating models from image data such as MRI and CT adds value to this approach by capturing the realistic anatomy of a patient, rather than relying on an idealized CAD model.

New solutions are tackling the challenge of linking together 3D scanning with image-based processing, simulation, and 3D printing. Several companies are engaging with these problems by utilizing the latest image-based techniques to build robust 3D printed models. The following examples look at the different ways that tumor therapy can be enhanced through medical 3D printing.

Tumor Raditation Therapy with 3D LifePrints

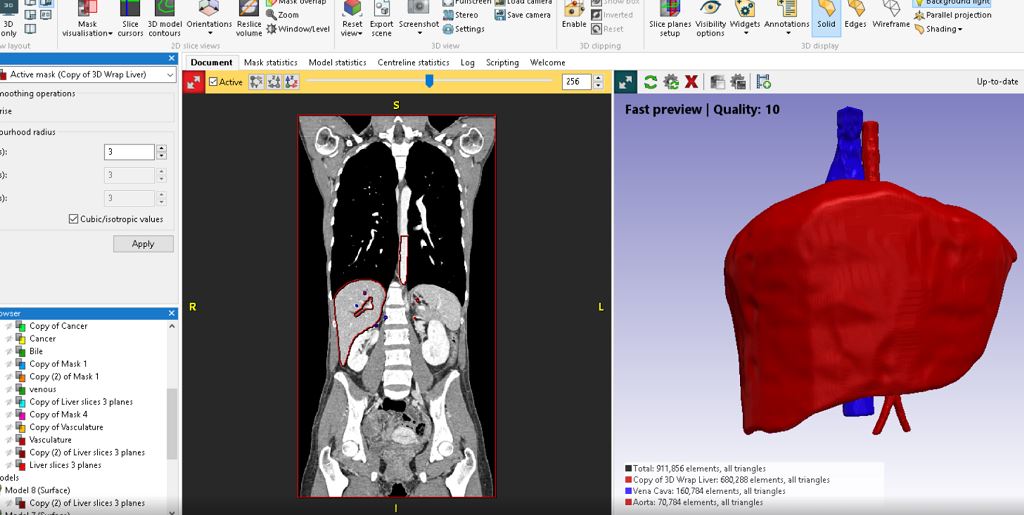

One example of these solutions comes from 3D LifePrints, a UK company that creates a variety of personalised medical devices using 3D technologies, and have recently manufactured a series of 3D printed physical phantoms of organs to help surgeons make more informed diagnostic decisions. 3D LifePrints use Synopsys Simpleware software to create models from imaging data.

The normal procedure for pre-assessment and planning prior to the interventional procedure relies on the clinicians looking for a variety of patient image data scans. The subsequent procedure uses X-rays to provide the targeted radiation dose for the area of interest. There are currently few options for planning other than CT/MRI scans shown on a 2D screen. The 3D printed phantoms manufactured allowed the surgeons to better understand the patient’s anatomy and by using the measured dosage and known cavity volume for the patient, the surrounding exposure on the liver could be estimated.

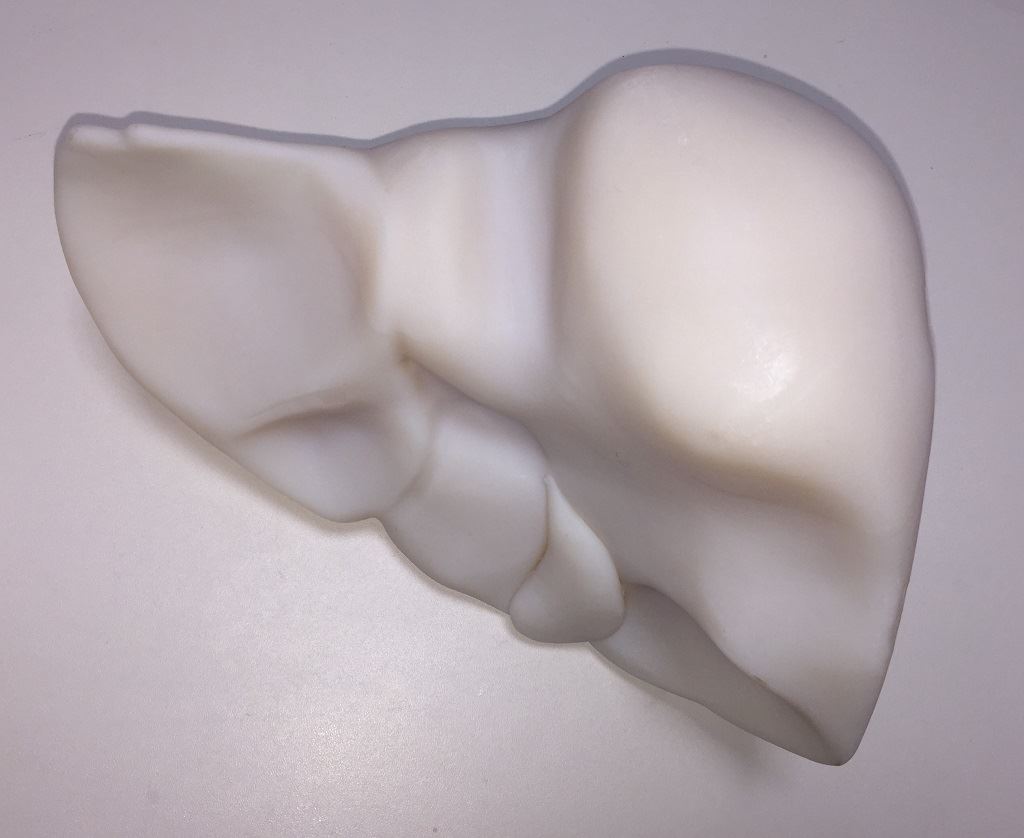

3D printed liver phantom in polymer [Source: 3D LifePrints]

A particularly successful project for 3D LifePrints involved creating a liver model to study dosage measurements for radiation therapy. 3D LifePrints obtained patient MRI data and segmented regions of interest in Simpleware software. Segmented images were then exported in a format suitable for 3D printing on a PolyJet machine. For this model, three chambers were included to hold radioisotope samples. The 3D printed phantom was then scanned using a Philips PET/CT machine and used to estimate the exposure of the liver to radiation through measured dosage and the known cavity volume.

![3D Printed Liver Phantom in MRI scanner [Source: 3D LifePrints ]](https://fabbaloo.com/wp-content/uploads/2020/05/lifeprints_05a_img_5eb094ce4d218.jpg)

Being able to identify the boundaries between the liver and the tumor is significant for customizing treatment pathways to individual patients. A 3D printed model is valuable for clinicians to understand the geometries of the tumor to more accurately calibrate the radiation beam diameters, thus reducing the risk of radiation exposure to the surrounding tissues. Paul Fotheringham, Founder and CTO at 3D LifePrints, comments as so:

“As a specialist medical 3D printing organization, the ability to have a functionally rich and effective medical modelling application is crucial in order for 3D LifePrints to meet our client’s complex requirements for medical devices.”

Visualizing Cancer Treatments with Wake Forest Baptist Medical Center

![Combination of different parts of the 3D printed model [Source: Wake Forest Baptist Medical Center ]](https://fabbaloo.com/wp-content/uploads/2020/05/wake_02a_img_5eb094ce92860.jpg)

Similar success has been achieved by researchers and clinicians at Wake Forest Baptist Medical Center in North Carolina, who use medical 3D printing models to visualize tumors for educating patients about cancer treatments. In this case, the Department of Radiology at Wake Forest Baptist Medical Center acquired patient-specific MRI data in DICOM format for segmentation in Simpleware software. Image processing tools were used to identify a tumor within a breast model, prior to generating .stl files of the breast and tumor.

![DICOM data from MRI scans were segmented in Simpleware ScanIP to generate two 3D models [Source: Wake Forest Baptist Medical Center ]](https://fabbaloo.com/wp-content/uploads/2020/05/wake_01a_img_5eb094ced6c27.jpg)

These models were then modified to ensure they could be effectively combined after printing. The breast model was hollowed so the printed part would represent the external shape without an internal fill – this means that the tumor model can be easily placed within the breast, and secured using a specially designed post to maintain the desired location.

![Breast model in transparent material and tumor in opaque materials to aid visualization [Source: Wake Forest Baptist Medical Center ]](https://fabbaloo.com/wp-content/uploads/2020/05/wake_03a_img_5eb094cf4d228.jpg)

The two .stl files were printed on a Stratasys J750 printer with Vero material. The three separate parts of the model, representing the two halves of the breast and the tumor, enabling clinicians to demonstrate the size and location of the tumor to patients through a visual aid. Physicians that used the models were impressed by how the 3D printed models aid patient communication, for example in demonstrating different treatment options.

More broadly, these types of models are valuable for visualizing patient treatments, particularly when printed using materials that mimic the appearance and tactile properties of a pathology and surrounding tissues. Patient-specific bioprinting is also an option for potentially generating replacement tissue that can be implanted to replace or regenerate an affected area. The use of biodegradable plastics and hydrogels can work here to create a multi-material solution. Carlos Kengla, PhD, Research Associate, Wake Forest Institute for Regenerative Medicine, comments:

“3D printed anatomical models are beginning to have a significant impact on medicine. The first step for patient specific model printing is segmentation of patient imaging data sets. Simpleware ScanIP makes that process simple and efficient as printable models can be quickly produced from segmented portions of the imaging data. We produced a model of the breast along with a tumor being treated, so the patient could better understand the diagnosis and subsequent treatment options being proposed by the physicians.”

Both examples show how medical 3D printing is providing solutions for simulating treatment options, and for effectively visualizing complex patient pathologies.

In the future, we expect to see medical 3D printing become a standard way of planning treatments and helping patients to understand clinical information that is often difficult to accurately describe.

FELIXprinters has released a new bioprinter, the FELIX BIOprinter, which is quite a change for the long-time 3D printer manufacturer.