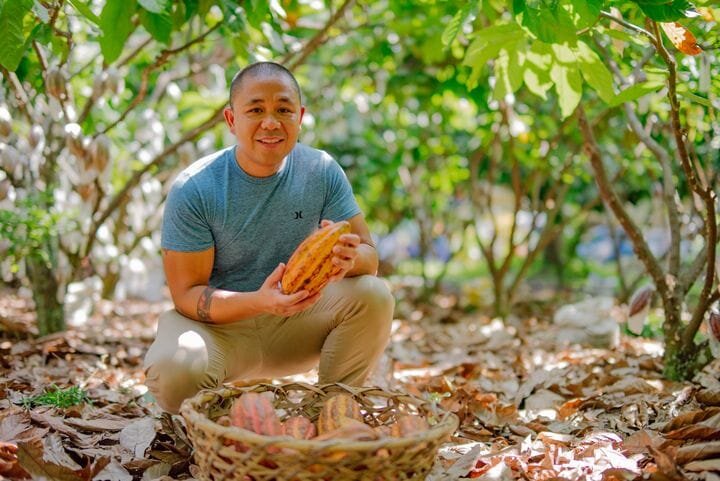

![Hernan Lauber at the beginning of the chocolate making process [Source: oodaalolly]](https://fabbaloo.com/wp-content/uploads/2020/05/HL_Pod_Kneeling_img_5eb08d9167c64.jpg) Hernan Lauber at the beginning of the chocolate making process [Source: oodaalolly]

Hernan Lauber at the beginning of the chocolate making process [Source: oodaalolly]

One of the materials often 3D printed experimentally is chocolate, but we have some questions.

Chocolate is an edible product, quite different from the solid mechanical parts usually 3D printed in metal or plastic. This means “taste” is a factor present in chocolate 3D printing that is not present in most other types of 3D printing.

However, chocolate 3D printer configurations are often built by non-chefs that perhaps have less understanding of taste challenges, and therefore I always wondered whether 3D printing is a technology that is suited for edible products.

To find out more, I reached out to Hernan Lauber, a San Francisco-based chocolatier, whose company, oodaalolly, produces small batch chocolate products.

Fabbaloo: What are your credentials in chocolate making and other disciplines?

Hernan Lauber: My name is Hernan Lauber and I am the founder / chocolate maker for oodaalolly small batch chocolate based in the San Francisco Bay Area. My history of working with chocolate goes all the way back to childhood. The reason my family moved to the United States initially is so that my father, who is a Swiss trained pastry chef who worked for an international hotel chain, could start a chocolate business with his business partner. The partnership lasted for almost a decade until my father decided to start his own business.

At that point, when I wasn’t in school or studying, helping my dad make chocolate and “working in the factory” took up all my free time. It was truly a family affair. My younger sisters helped out as well from an early age and we were expected to do everything except faster and more efficiently than anyone else, it is Swiss business after all because all the bulk chocolate was imported from Switzerland. I worked in that business all the way through college where I studied mechanical engineering and graduate school where I studied International business. So in may ways, founding oodaalolly was an unexpected turn to chocolate.

Fabbaloo: Are you aware of 3D printing technologies used to produce chocolate? What have you seen?

Hernan Lauber: Having an engineering background, I’ve been aware of 3D printing technology for some time and have been fascinated with its applications. Also I have been very good friends with the owner of Joy Complex, Jeremy Burnich, for close to a decade and he’s very much involved and in-tune with the technology so he always forwards on anything that is 3D printing / chocolate related.

That being said, what I have seen is interesting from a novelty item or architectural perspective. It’s interesting to see really intricate designs or items recreated or produced with chocolate as the raw material. But what I haven’t seen yet is a truly commercial application where I thought – that’s a really interesting use of the technology where it would also be a new or interesting way to produce a confection or an edible item.

Fabbaloo: What is it about chocolate as a material that makes it so tricky to handle and make properly edible products?

Hernan Lauber: There’s a variety of factors some of which have been mentioned on previous posts. The structural integrity, the melting factor when handled, the limited time frame that you have to manipulate the chocolate while hardening, the need to temper to develop the right look / feel for the chocolate once hard.

I think another thing to consider is also the expectation of what chocolate is and what it is being used for. Most people have a certain perception of what chocolate is and I think the evolution would need to come from the application or use. Similar to how savory chefs use foams or smears to enhance dishes or to manipulate ingredients to behave differently, is there an application where 3D printed chocolate could be used in this way? I am not sure what the boundaries are and that’s what makes it interesting.

![Pouring liquid chocolate [Source: oodaalolly]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08d91ad867.jpg) Pouring liquid chocolate [Source: oodaalolly]

Pouring liquid chocolate [Source: oodaalolly]

Fabbaloo: Many chocolate 3D printing ventures seem to simply heat a supply of chocolate to the appropriate degree of softness and then extrude it through a syringe. As an actual chocolate maker, what goes through your mind when you see this approach?

Hernan Lauber: This goes back to what is the application? An extruded shape, ok now what? If we are just re-creating something that can already be done using other traditional techniques then fine. But I think it needs to be pushed beyond those boundaries to make it truly exciting.

Fabbaloo: Is a tradeoff between 3D object structural integrity / resolution & detail vs. chocolate taste feasible? Must you sacrifice one for the other?

Hernan Lauber: Well my first question is how many 3D printed chocolate items are intended to be eaten? I think with current constraints, there is a trade-off or sacrifice that must be made.

Fabbaloo: Chocolate can be a poor structural material when softened. Does this mean it will never be possible to print complex chocolate 3D objects?

Hernan Lauber: Never say never is my philosophy. I don’t think anyone’s yet to make the right mistake to enable complex chocolate 3D objects? As I was typing that, gelatin just jumped into my mind. Gelatin is commonly used is pastry to help create some additional structure for pastry applications. Has anyone tried using gelatin with chocolate? I’m curious to know?

Fabbaloo: We recently wrote a story on how scientific researchers were able to 3D print “chocolate” without heating by mixing in syrup and cocoa powder. Do you think this is a valid approach? Is it even chocolate?

Hernan Lauber: At oodaalolly we have a very traditional sense of chocolate. We use minimal ingredients for our chocolate bars. For example our 70% dark bar has cacao and sugar, that’s it. So even though that is my philosophy on chocolate making, I have no concerns about people experimenting with different techniques and ingredients. That is a totally a valid choice and as long as there is cacao, it is chocolate based products.

Here’s a quick little anecdote. Your standard chocolate eating consumer probably prefers milk chocolate to dark chocolate. Milk chocolate is a little sweeter has a bit of a creamier texture and it’s what many people think of when they think chocolate. What is interesting about that, to me at least, is until the 1870s when Daniel Peter decided to experiment with introducing a powdered milk product into chocolate, there was no milk chocolate. So that’s a perfect example where introducing a new ingredient pushed the entire chocolate world forward.

So if you can innovate, go for your life…

Fabbaloo: We know of at least one company that claims to produce suitably tasty large format chocolate 3D prints, although they won’t say exactly how they achieve their results. Any guesses as to what they may be doing?

Hernan Lauber: Magic? My mind also went first to some sort of additional cooling technique.

Fabbaloo: Assuming a working chocolate 3D printer could be produced and sold, who do you think might be the buyers? Would this ever be a thing found in residential kitchens, or this is forever to be a commercial kitchen / industrial phenomenon?

Hernan Lauber: I think pastry chef or caterers might be the first buyers. They are typically the ones that are trying to create that show-stopper for an event. My dad makes my kids chocolate mustache lollipops and dog shaped lollipops which they love so if there could be a residential kitchen version for kids to make their own chocolate lollipops in fun shapes, that could be cool.

![A collection of oodaalolly chocolate products [Source: oodaalolly]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08d9200caa.jpg) A collection of oodaalolly chocolate products [Source: oodaalolly]

A collection of oodaalolly chocolate products [Source: oodaalolly]

Fabbaloo: In your chocolate production operation, how could you see a chocolate 3D printer being used? Would chocolate workshops be able to make use of such a device?

Hernan Lauber: One of things that we have talked about is the best way to incorporate liquids into our bars, for example a rum or other liquor in a cost effective way. Traditionally you would form a chocolate cavity in a mold and then fill it with the ganache or liquid or you could co-extrude the ganache with an outer chocolate shell. I am wondering if there is something a 3d printer could do differently to solve this problem?

I am sure there are other applications or uses for 3D printing in chocolate but we have probably just scratched the surface of what is possible.

Via oodaalolly