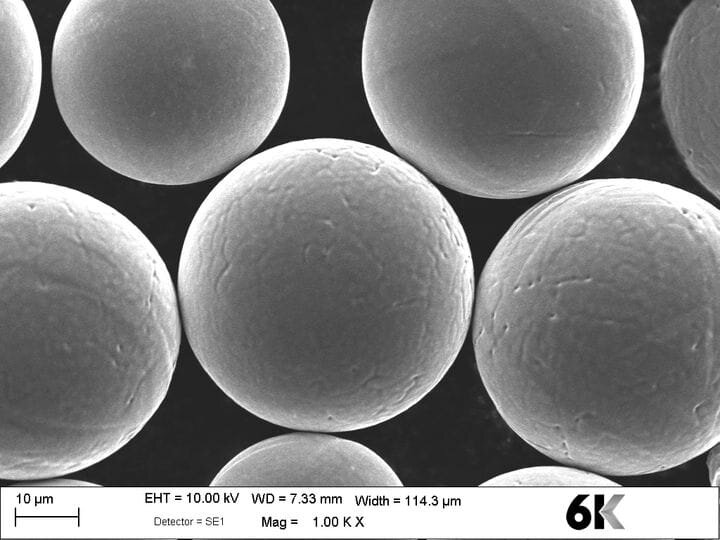

![Incredibly spherical metal particles made by the Unimelt process [Source: 6K Additive]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08d6eaf3c0.jpg) Incredibly spherical metal particles made by the Unimelt process [Source: 6K Additive]

Incredibly spherical metal particles made by the Unimelt process [Source: 6K Additive]

6K Additive introduced “Unimelt”, their new microwave plasma-based process for precision powder production.

AM Powder Production Challenges

While it is well-known that powder quality is of utmost importance in achieving the highest quality 3D prints, today’s powder production systems can’t yet produce “perfect” powder. Now it seems that 6K Additive has created a new way to make powders that are significantly higher quality – and less expensive.

The typical method of creating powder involves a gas plasma, whose high temperatures vaporizes input feedstock and forms particles as the temperature cools. However, the imprecision of the process often results in porosity of the powder: the particles are not always perfectly spherical.

When 3D printing such powders, the pores can result in gaps in the final print, lowering part quality.

6K Additive Unimelt Process

The Unimelt process gets around these issues by using tunable microwaves to generate a 6,000K plasma, the same temperature as the surface of our sun. In fact, that’s how they named the company, get it? The microwave approach allows 6K Additive to very precisely control the temperatures during processing, and this allows them to create near-perfectly spherical powders.

The advantage of high quality powder are clear: perfectly dense parts with no flaws.

Sustainable Metal Powder

If that wasn’t enough, 6K Additive has another angle: sustainability.

Their process is able to accept recycled material, such as CNC machining scraps, support structure cut-offs, or failed prints as input feedstock. Their process will mill, clean, press and dry the feedstock to a state where it can easily be processed into precision powder using Unimelt.

Recycling material is of incredible importance for several reasons:

-

It can dramatically lower the cost of feedstock, and thus lower the cost of powder

-

It can reduce dependence on foreign sources of powder by enabling access to domestic sources

-

It can reduce waste materials that might otherwise be literally buried in the ground

Reusing AM Metal Powder

There’s another twist to this capability: the input feedstock could be used metal powders that are normally only partially used in metal 3D printers. In other words, 6K Additive’s Unimelt process can rejuvenate used powders! Actually, it’s more than just rejuvenate, as the powder produced is likely of higher quality than the original state of the input powder.

Unimelt works with both metal and thermoplastic materials, although the company intends on focusing on metal powders for the moment.

Custom Alloy Metal Powder

![3D printed metal rocket nozzle using 6K Additive metal powder [Source: 6K Additive]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08d6f0bfd3.jpg) 3D printed metal rocket nozzle using 6K Additive metal powder [Source: 6K Additive]

3D printed metal rocket nozzle using 6K Additive metal powder [Source: 6K Additive]

One of the most interesting aspects of Unimelt is its ability to combine metals that would not normally be alloyed using conventional powder production processes. It’s not quite clear how they do this, but it allows operators to choose very specific, custom-made alloys for their use.

In order to showcase the capabilities of Unimelt, 6K Additive has produced a wide variety of sample powder materials to demonstrate the capability of the process. We understand they’ve so far made these powders:

-

Ti-64

-

IN718

-

IN625

-

YSZ-8

-

Stainless 17-4

-

W

-

Ta

-

Mo

-

Rhenium

-

AlSi10Mg

-

Aluminum 6061

-

High entropy alloys

-

PEEK

-

Graphene-impregnated nylon

As you can see, this process has very wide capabilities. 6K Additive says they can produce “any ratio” of input materials to create virtually any alloy.

6K Additive Business Model

Their business model is to establish a central factory to produce these powders, which would be sold worldwide eventually. They intend on starting with their Boston/Pittsburgh plants, but anticipate setting up similar facilities in Europe and Asia in the future.

Their technology seems to enable a variety of unusual business models. One mentioned was the notion of a “factory within a factory”. In this concept, a client could set up their AM operations within or nearby the 6K Additive facility. Then, any scraps, waste or used powder could be directly transformed back into usable high quality powder by 6K Additive and immediately used.

Another striking implication I observed involves the partnerships typically undertaken by traditional powder manufacturers. In many cases such operations have directly partnered with / acquired / or began as a metal source, like a mining operation. This is done to ensure a smooth flow of consistent quality feedstock for powder production.

But in the case of 6K Additive, there is no need for such a partnership, as their feedstock comes from local areas as recycled metals. This is an incredible advantage.

Will industry catch on to use of recycled powders? 6K Additive believes so, as they say as much as 70% of metal ingots used by industry today is already recycled. The difference is that no one has figured out how to provide recycled powder – until now.

6K Additive currently has grown from only three people to around 100 in only four years, and has invested tens of millions into their new plants, ready for large-scale production.

I believe 6K Additive’s products could dramatically shake up both the AM powder industry as well as the many metal 3D print services currently using conventional powders.

Via 6K Additive