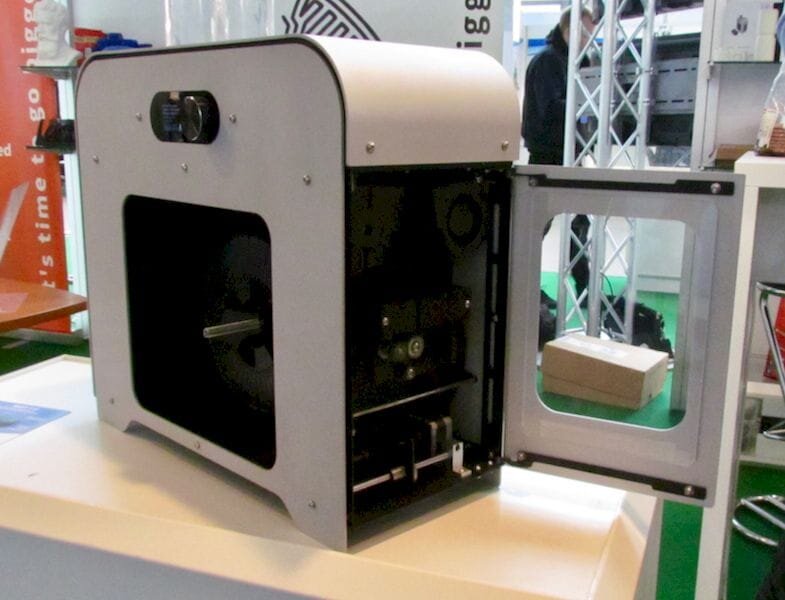

![The 3DEVO filament maker [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08d4bbc899.jpg)

3DEVO intends on opening an office in the USA.

The Netherlands-based company has selected the state of Delaware as their office location, from which they will coordinate North American operations. This is apparently the very first foreign office for the company.

3DEVO USA

Why do so? They explain:

“A U.S. presence will help his company improve the purchasing process for its overseas clients. In addition to shortening lead times and speeding up deliveries within the U.S. and North America, it will also facilitate payments by eliminating currency conversion and other logistical obstacles.”

I’m thinking this is a bit of a milestone for the industry, based on the specific product line produced by 3DEVO.

3DEVO Filament Maker

3DEVO’s claim to fame is a desktop device that can produce practical 3D printer filament from either scrap material or raw industrial thermoplastic pellets. Normally, 3D printer filament is produced en masse at large factories with warehouse-sized production lines filled with equipment to handle the various stages of filament making.

But 3DEVO’s device literally sits on a desktop.

Desktop Filament Production History

There’s a bit of history here. I’ve seen plenty of desktop filament-making devices over the past years, and virtually all of them failed miserably. It turns out that production of usable 3D printer filament is actually a very tricky thing to do.

Why? Because it is a matter of precisely maintaining multiple temperature zones, ensuring consistent input material, maintaining correct humidity and keeping throughput speeds constant. While the basics of the process are straightforward – heat some plastic and push it through a nozzle – the magic is in the combination of all the above factors.

There’s another problem, too: capturing the output. Early 3D printer filament devices for the desktop somehow ignored this and I’ve actually seen such devices spilling out fresh filament into a spaghetti-like knot on the floor beside the machine. That is totally unusable for 3D printing, yet such devices were actually marketed to the public.

They all failed, more or less.

3DEVO Success

But one company has not: 3DEVO. Somehow they’ve managed to create a device that does precisely balance all required factors to produce highly usable 3D printer filament. And it’s often less expensive than buying pre-made filament off the shelf if you are able to feed 3DEVO’s equipment from a supply of industrial resin pellets.

However, that doesn’t seem to the prime use of their Filament Maker. Instead, it appears that many of their clients seem to be using the equipment for production of custom filaments that would not normally be for sale at the usual outlets. By obtaining unusual input material such operations are able to make unusual combinations of composites or colorations, sometimes for experimental purposes in laboratories.

![3DEVO’s plastic scrap shredder for preparing input material to their filament maker [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08d4c19b78.jpg)

Since the introduction of their Filament Maker, 3DEVO has gone on to develop a variety of associated equipment, including filament dryers and plastic recyclers that complement the filament making process.

Their approach has been quite successful, and now we see they are expanding across the ocean, something I never imagined a desktop filament maker might be able to accomplish.

3DEVO has figured it out.

Via 3DEVO