![3D printed micro-needles [Source: Wiley]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb050a9b369c.jpg)

Researchers have used a micro-3D printing technology to produce an effective long-term drug delivery needle system.

Everyone is familiar with the standard hypodermic needle, and some of you might be terrified by the thought of having one. The hypodermic needle delivers an entire dose of medication in a few seconds (although it may seem to be far, far longer). But what if you needed to deliver drugs continuously over a longer period?

The thought of having continual hypodermic needles is indeed frightening, and because of that “microneedles” have been developed. These “pain-free” needles are attached to the body for longer periods, during which they deliver drugs to the patient as per requirements.

But there’s a problem: these microneedles, though pain-free, don’t stick very well. They tend to fall off and must be re-applied to the patient. This is inconvenient and perhaps dangerous if the meds are of a critical nature.

![3D printed micro-needles [Source: Wiley]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb050aa0859a.jpg)

Now researchers at Rutgers and the University of Pisa have developed a “4D Printed Microneedle Array”, using advanced microprinting technology. Specifically, they used the PμSL process from Boston Micro Fabrication, of which we wrote a few days ago. This technology allows 3D printing on tiny scales, with resolutions around 0.002mm.

The researchers turned to nature to see how this is best done, as there many examples in nature. Anyone who’s been stung by a bee would know this intimately. The researchers found that needles with barbs provide 70X more adhesion, and that’s exactly what was required.

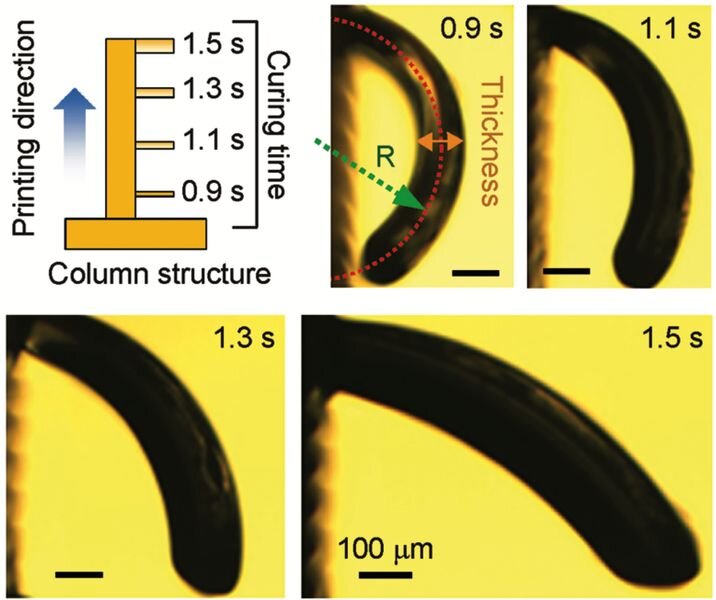

They designed a needle system with rows of barbs, as seen in these images. The interesting part was the barbs. The researchers found a way to implement various degrees of barb curvature by modifying the post-processing steps for the 3D prints. They could make the barbs curve tightly inward, providing lower adhesion, or have them stick out almost fully, providing maximum adhesion.

![3D printed micro-needles barb positioning process [Source: Wiley]](https://fabbaloo.com/wp-content/uploads/2020/05/microneedle-4d-process_img_5eb050aa4b76b.jpg)

Depending on the application, one could choose the appropriate level. The researchers found their design to even exceed that of natural microneedles!

![3D printed micro-needles barb positions [Source: Wiley]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb050aa89a4b.jpg)

The microneedle is also built as an array. As you might imagine, an individual needle cannot deliver a great deal of meds, so this is overcome by parallel delivery through an array of microneedles.

In fact, the researchers say that it would be possible to create arrays that are larger than the build volume of the BMF 3D printer by using a “shift and repeat” process. I believe this is due to the nature of the PμSL process, which seems to project light patterns onto a subsection of a liquid photopolymer vat.

Finally, they were able to test their design using a chicken breast, which received continuous drug delivery for a period of six hours. I suspect the chicken breast did not complain about any pain.

Via Wiley