We’ve always been slightly annoyed at the overly simple manner in which 3D models are sliced and printed. Much more is theoretically possible and that may now become reality with the work developed by Project Silkworm.

If you, like us, spend hours ponderously watching your 3D printer extruder tediously traverse the print bed, gradually building up an object, you’ll start to imagine things. Better ways to extrude. Different directions. You’ll ask yourself, “why can’t it move like THIS instead?”

It’s because the commonly found 3D model slicing software takes a very straightforward approach: cut the model into equally sized slices and print them on top of each other. That’s it. It’s done this way to ensure a reliable print.

But it also restricts things considerably. Why couldn’t we have fatter extrusions in the interior, for example? Why can’t we move up AND down during a print?

Project Silkworm attempts to get at this issue. It works with software modeling Rhino3D and its popular plugin, Grasshopper. Here’s the official description:

Silkworm is a plugin that translates Grasshopper and Rhino geometry into GCode for 3d printing. Silkworm allows for the complete and intuitive manipulation of the printer GCode, enabling novel printed material properties to be specified by non-solid geometry and techniques of digital craft.

Whoa. Hold on.

This means you are developing the print movements DIRECTLY from your CAD software. You know, the CAD software that has far more sophisticated processing capabilities and also happens to intimately know the geometry of your object.

This opens up endless possibilities. Some of them have been explored by the project. Their example page includes these:

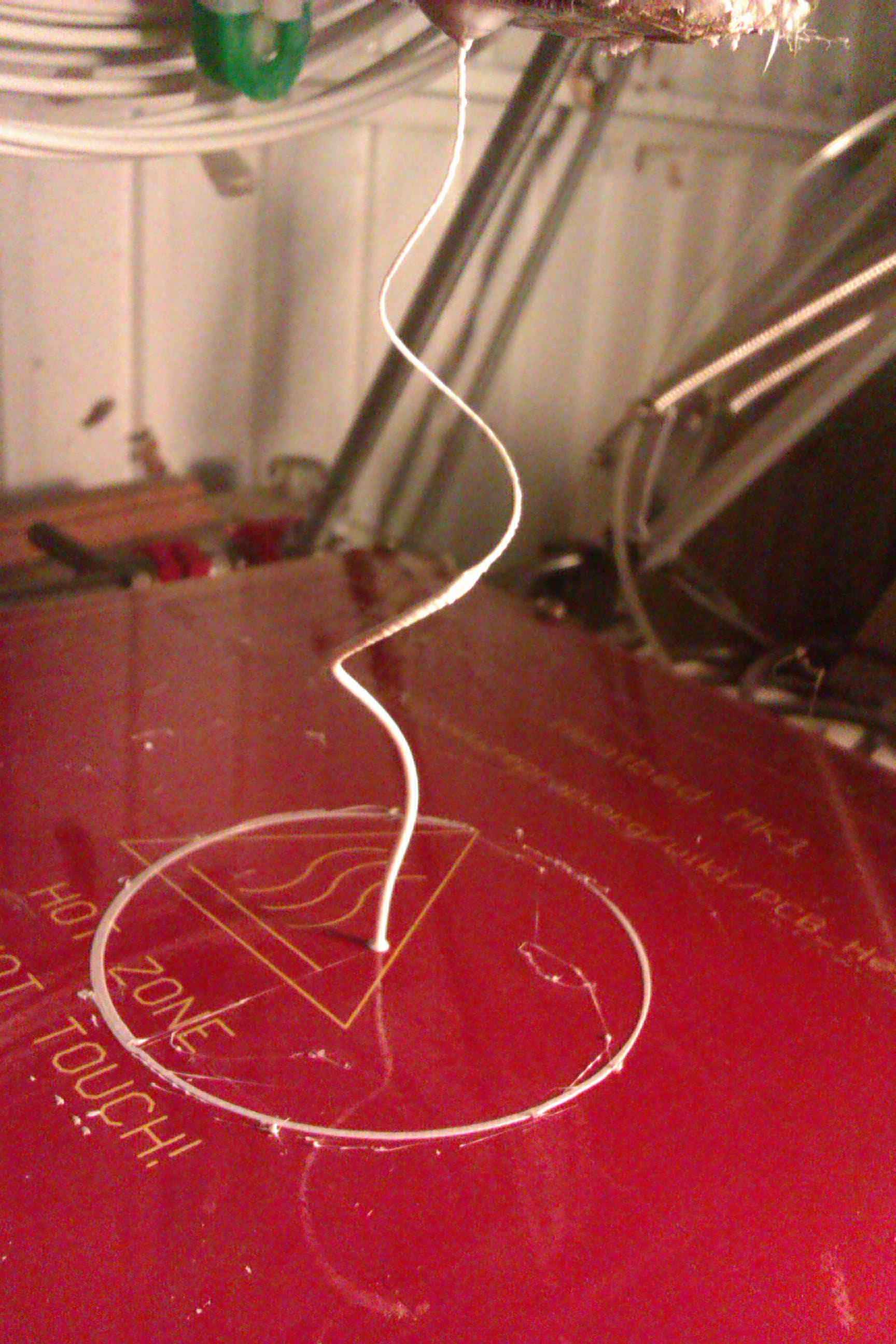

- Build a continuously extruded spiral with a range of different speeds and flows, making fatter and thinner extrusion lines.

- Add contours and “grain” to an otherwise flat surface.

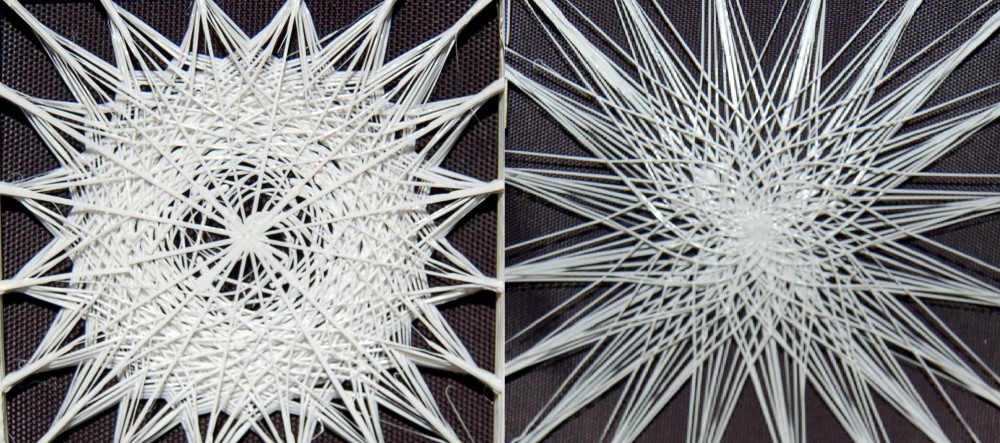

- Extrude a continuous structure upwards on the Z-axis in one operation

- Create a continuous unsupported spiral by using very slow extrusion speeds

- Vary extrusion settings for specific zones

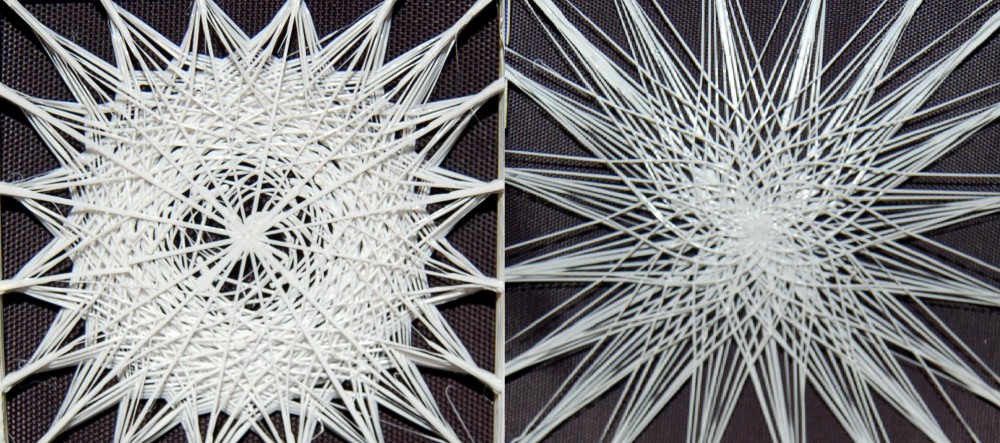

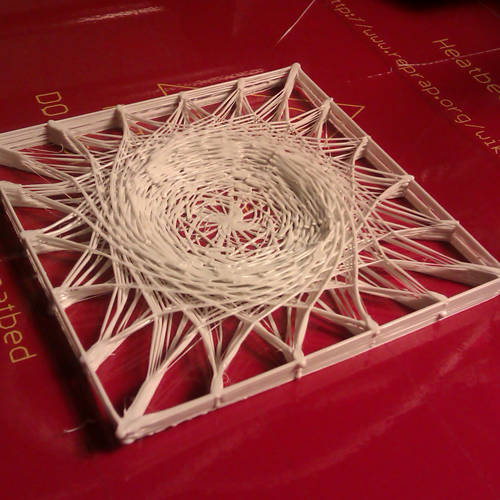

- Extrude a “layered pattern weave” using vector field geometry

This incredible capability, while still experimental, is available at no charge. All you need is a working copy of Rhino3D on Windows with the Grasshopper plugin.

We can only imagine what people will do with this capability.

Via Project Silkworm (Hat tip to Frederico)