A new consortium in the UK has been established to develop and promote the use of WAAM 3D printing technology for commercial applications.

WAAM is an abbreviation for “Wire-bAsed Additive Manufacturing”. It’s a relatively uncommon 3D printing process used by only a few companies, but it offers some unique capabilities.

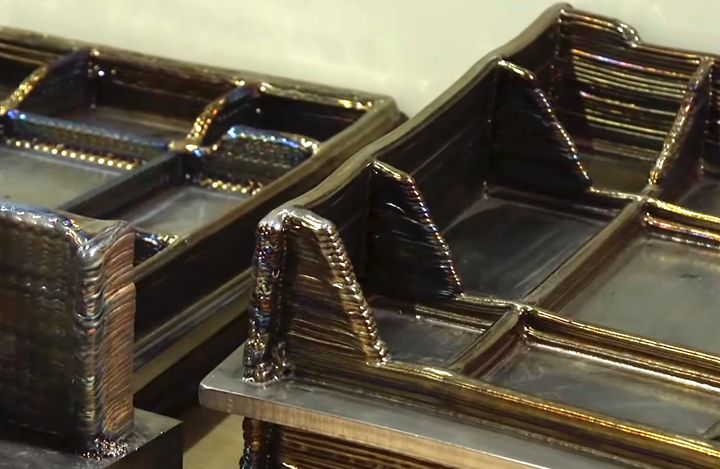

WAAM works much like a welder: a wire of source metal material is exposed to high energy, which causes the metal to instantly melt. By moving this melting point in 3D, it’s possible to gradually build up a fully solid 3D metal object.

WAAM-style systems can use a variety of energy sources, including lasers, plasma or electrical arcs, to rapidly heat up the metal wire. Motion systems can be either Cartesian gantries or, more typically, robotic arms with special WAAM-equipped toolheads.

Due to the nature of the motion systems and melt characteristics, WAAM is typically used to rapidly build larger 3D objects. Its resolution is not particularly good, but the print speed can be quite fast.

WAAM has been researched by scientists at Cranfield University for over 15 years Their work is being commercialized by a startup, WAAM3D, based in Milton Keynes, that incorporated in 2018. Their official mission statement is:

“To provide all the necessary tools and technical solutions needed for widespread adoption and exploitation of wire-based AM through a coherent ecosystem that responds to every users needs for the implementation of wire-based AM.”

The news is that there’s a new project called “HPWAAM” that’s funded by Innovate UK with intentions of developing a “novel solution for a UK industrial sector”.

Note that the letters “HP” in “HPWAAM” absolutely do not mean the company HP is involved in the project. Let’s make that perfectly clear. Rather, HPWAAM stands for High Productivity Wire Arc Additive Manufacturing.

Who is involved? Here’s a list of the seven participants:

- BOC — a member of the Linde Group, is a leading industrial gas provider

- Cranfield University — a wholly postgraduate university based in Bedfordshire

- Foster + Partners — an international design studio

- Steelo — a lean manufacturer of construction systems

- WAAM3D — a spin-off company from Cranfield University

- Weir Group — a global mining equipment leader

- Wintwire — a specialist SME wire manufacturer

This is a very interesting group, as it seems to have representatives from all necessary skill sets: research, design, materials, gas, application, marketing, distribution. And WAAM3D to tie it all together.

Innovate UK has provided the three-year project £1.2M (US$1.65M) to take on this work. WAAM3D explains:

“This business-led, commercially focused project involves a powerful consortium to deliver ambitious technology targets and will support an industry-focused ecosystem for the wide-spread adoption of Additive Manufacturing in applications such as construction and resource industries.”

This should be good news, as the WAAM process is probably not used as widely as it could be. I suspect if made more visible and demonstrably useable by industry, as this project intends, then some manufacturers will adopt it.

It’s a given that change is difficult and that has always been the case with 3D printing. Businesses are always skeptical until shown that something really works, and until then they will happily continue doing their work in the usual manner.

I hope they succeed!

Via WAAM3D