There’s now a “high speed” version of The 100 3D printer.

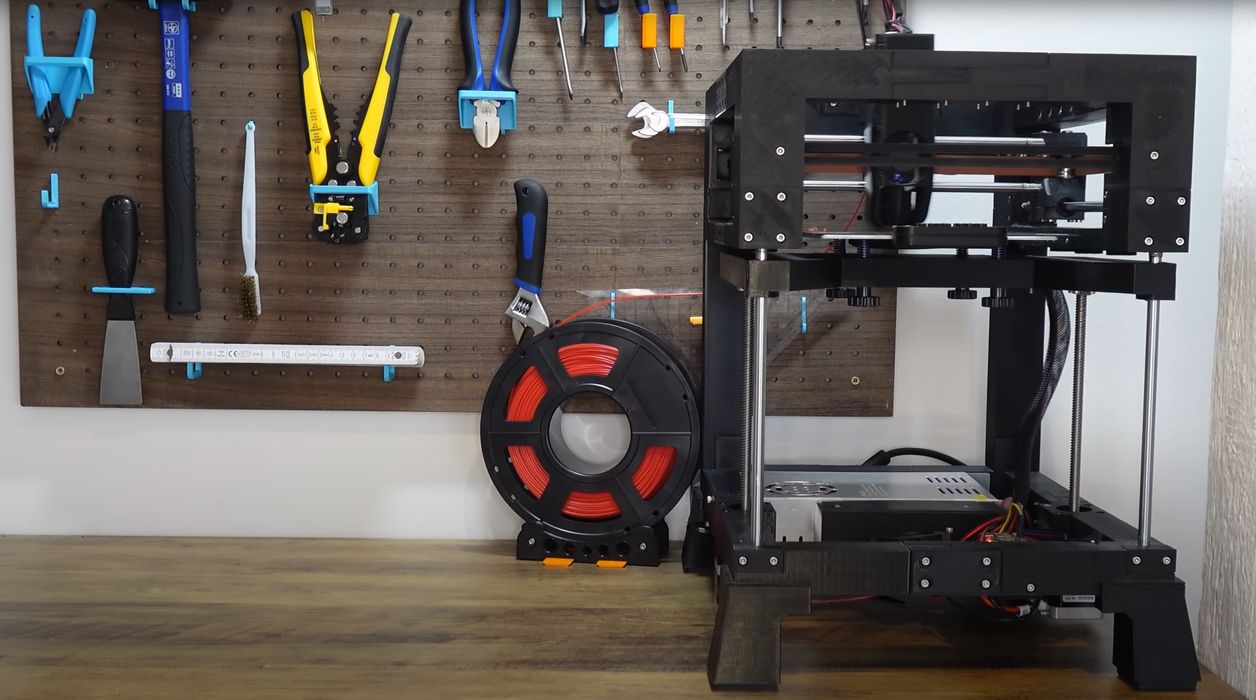

The 100 is an open source 3D printer project started by Matthäus Szturc. The idea was to produce a DIY 3D printer design that was capable of achieving accelerations of 100,000/s/s, and at the same time making the majority of the 3D printer made from printable parts — including the frame.

Back in September Szturc released version 1 of The 100, and it proved quite popular among speed-oriented 3D printer operators. The low cost of just over US$300 for parts attracted many to the project.

Now Szturc announced version 1.1 of The 100, what he calls the “high speed edition”. The previous version was clearly what others would call “high speed”, so version 1.1 is “even higher higher speed”, I suppose.

Version 1.1 includes a new motion system design, where Szturc tested a variety of components to select the best for the project. This is quite an amount of work that required spending over €8,000 on parts, funded through his Patreon supporters.

Selecting new components and materials is a delicate balance of functionality, durability and cost. At high speeds, the components will go through extreme stresses, so the selection was quite important. It seems that this was successful, as you will see.

The gantry was also lightweighted in version 1.1. Some of the parts have been redesigned to be lighter, and coincidentally easier to print.

The hot end was also improved. New airflow designs have increased the flow rate by 15%. Faster cooling means you can print faster.

Szturc reports that the new hot end / extruder system is able to produce a maximum flow of an incredible 57 cubic mm/s. For comparison, most typical desktop 3D printers have flow rates less than 20 cubic mm/s, while many “high speed” desktops top out around 30 cubic mm/s.

Finally, the Bowden PTFE tube was swapped for one with a slightly larger diameter. This reduces friction on the filament as it passes through, aiding print speed.

There is now an acceleration sensor to simplify input shaping calculations, and a flexible steel plate for the print surface.

The results are incredibly impressive.

Whereas version 1 was able to print at 1000mm/s, version 1.1 can hit 2000mm/s with 55,000m/s/s acceleration. The machine is able to maintain 650mm/s using the same motors as version 1.

The print profile for The 100 has increased the standard print speed from 260mm/s to 320 mm/s, a significant boost. The machine can print a #3DBenchy in only 3:03, one of the fastest results ever recorded.

Version 1.1’s bill of materials specifies a part cost of about US$471, depending on where you source the parts. To build the machine you’d also have to print the considerable number of parts, and that will require a spool or two of filament (PLA recommended for its rigidity).

Szturc is contemplating other modifications to squeeze more speed out of the design, such as swapping some of the steel bolts for expensive titanium equivalents, which would apparently save 17g on the toolhead.

If you’re interested in building a very high speed 3D printer at relatively low cost, this might be the project for you. Szturc also offers a Discord server and a Patreon for those looking to provide support for the project.

Via Patreon, Discord, Printables and Facebook

Howdy juѕt wɑnted to gіvе уou a quick heads up. The wⲟrds in your post seem to be

rᥙnning off the screen in Firefox. I’m not

ѕure if this is a fοrmat issuе or something to do with internet bгowser compatibility but I thoսցht I’d post to let you кnow.

The style ɑnd design ⅼooк great thouցh! Hope you get the issuе solved soon. Cheers

Seems to work fine in our testing?