An announcement by Xaar leads to some interesting speculation about Stratasys’ future strategy.

Xaar Print Heads

Xaar is a German company that manufactures high-speed inkjet print heads, which they call “industrial inkjet technology”. Xaar uses the “drop on demand” approach, which allows for precise, yet very high-speed printing. You can see how their process works in this short video:

This type of product is normally used in large-scale 2D printing operations such as you might see at a newspaper. However, some of Xaar’s components can be repurposed specifically for use in high-speed 3D printers. For binder jet-style 3D printing a liquid binder must be selectively deposited. This could be done with an inkjet print head. Similarly, resin 3D printing processes that use deposition (like Stratasys’ PolyJet) can also make use of this style of print head.

Xaar and dp polar

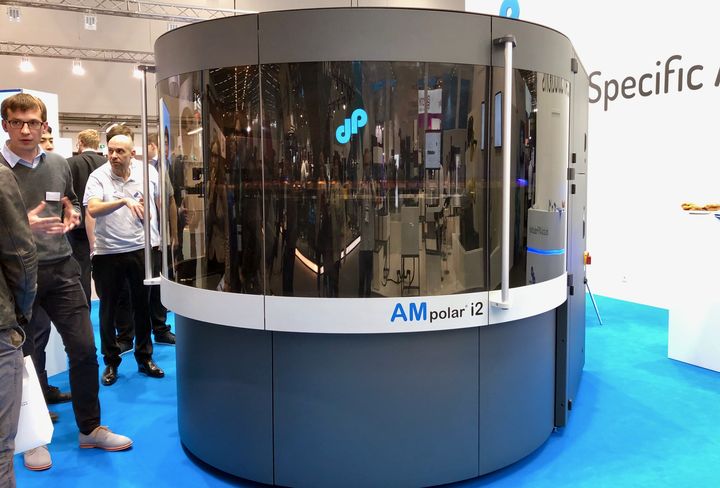

This week Xaar announced their 1003 model print head is being used in dp polar’s AMpolar i2 3D printer. They say:

“The AMpolar i2’s patented Additive Manufacturing process uses an array of Xaar 1003 printheads to jet parts at volume, and at a significantly reduced cost when compared to traditional 3D printing machines.

The highly productive single-pass printing process delivers build volumes of up to 700 litres across its pioneering, continuously rotating print platform. For example, the AMpolar i2 machine is able to produce over 500,000 automotive electronic power-plugs per year at the lowest costs per part. Achieving the same output with traditional 3D printers would require the operation of multiple machines, requiring substantially more initial investment, and increasing costs and complexity across production.”

The AMpolar i2 is a truly interesting 3D printer, as it uses a gigantic rotating plate under the print heads (now known to be Xaar 1003’s), which selectively deposit material. It’s quite something to see it in operation, as the huge print plate spins quite rapidly.

For Xaar, this is an excellent outcome as it demonstrates the utility of their products in a new and exciting industrial sector: additive manufacturing. I’m certain they are anticipating additional sales as interest in production manufacturing increases.

But there’s another big twist to this story.

Stratasys Xaar Relationship

Stratasys owns 45% of Xaar, as we reported last year. In fact, we’re told Stratasys intends on acquiring the remainder of Xaar in the future. Thus it would seem that the AMpolar i2 could be based on Stratasys technology.

We’ve suspected for quite some time that Stratasys’ long-term strategy involves moving to large-scale production equipment, as they’ve made several moves towards that goal in recent years, such as producing a series of industrial technology demonstrators, or developing a digital inventory solution, specifically for the rail industry, but likely to extend to others. I think this could another step in that direction.

Because of those moves one might think Stratasys is developing one or more large-scale industrial 3D printers targeted at major manufacturers. That may still be true, but the Xaar investment and work with dp polar suggests another angle on their strategy.

It may be that Stratasys could in the future be interested in acquiring dp polar or its technology if it is successful. But another alternative is that Stratasys rides the wave of manufacturing interest by supplying sophisticated components to others in the space. Like, for example, selling print heads to 3D printer manufacturers as they have apparently done with dp polar via Xaar.

This is actually a brilliant strategy, as it allows them to leverage others’ work in the space but continue to sell products.

It’s like selling shovels to the miners.

Via Xaar