Charles R. Goulding and Adam Friedman check out 3D printing used for building new robots that may help slow the spread of pandemic.

As seen on CNBC, Bloomberg and Fox News, hospitals, nursing homes, hotels, offices and other establishments trying to limit the spread of the coronavirus have become instant customers for ultraviolet C (UVC) robots. These robots use UVC light to thoroughly disinfect surfaces where pathogens and viruses live, a task typically completed manually. What makes these robots advantageous and preferred over standalone or human-operated UVC lights is the ability to effectively minimize human exposure to harmful UVC light. According to Chief Executive Melonee Wise of Fetch Robotics says, “there has been a surge of demand for disinfection robots.” Record volumes of machines are being ordered and companies have begun manufacturing UVC disinfectant robots on a global scale.

3D printing is an ideal technology for building UVC robots at a rate that meets global demands.

It has been a standard process to create a robot’s solid metal base and add to its structure with the necessary outer components. Another approach can be taken using 3D printing to design and create durable components. Successful 3D printing methods could effectively decrease the production time of the machines.

Boston Dynamics

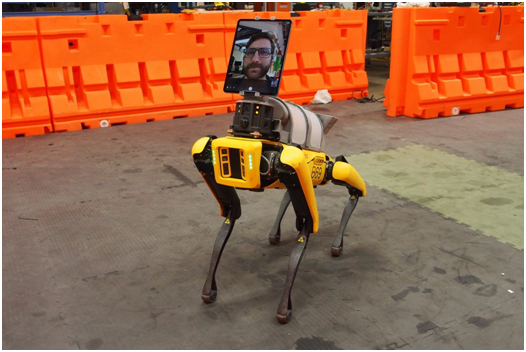

Boston Dynamics, an important player in the robotics industry, has a long history with optimizing robots using 3D printed parts. In 2016, Boston Dynamics made public their four-legged robot named Spot, which features an internal body where additional devices and robotic parts can be attached to its frame.

In addition to deploying the quadruped for telemedicine applications, the company has recently begun designing a UVC lamp attachment for Spot in response to the novel coronavirus pandemic. On this body, UVC lamps and components are mounted, providing Spot the equipment to operate as a traveling disinfectant robot. Spot can then be programmed to shine UVC light in any unstructured space where pathogens are located and notify workers of the total area where UVC light is emitted. Perhaps 3D printing will be used to more quickly develop and test various components, such as the base, arm, light mount, and wiring casings.

University of Southern California

A team of researchers at the University of Southern California (USC) Viterbi Engineering School has emerged as another key player in the UV disinfectant robot market.

In 2017, USC Engineering created ADAMMS (Agile Dexterous Autonomous Mobile Manipulation System), a robot designed to support repetitive human tasks. Three years later, in the wake of COVID-19, the team adapted ADAMMS to be a UVC disinfection tool, made possible by 3D printing necessary additional components. Additionally, the team has said that 3D printing can be used to further customize the robot to make it suitable for smaller spaces or specific perfunctory applications.

CounterBot

An industrious Washington native and mechanical engineer, Jeffrey Kerr, invented a UVC robot for which he used 3D printing to build. The robot is called the CounterBot and automatically traverses flat surfaces and focuses UVC light onto unclean areas. CounterBot has a 3D printed shell with attached UVC light bulbs and a hand held sanitizer unit inside its outer shell.

As of May 2020, a Kickstarter campaign has been started by a company called Smartify, which seeks to commercialize this idea. Kerr has allowed the use of his original prototype in exchange for a small donation to the World Health Organization.

Standard UVC Robots

UVC disinfection robots that are not produced using means of 3D printing have also been proven to be a viable solution for cleaning virus and pathogen prone areas. As the novel coronavirus pandemic continues, companies developing solutions to improve the design and functionality of existing models may be eligible for state and federal R&D tax credits to help.

YouiBot Robotics

Founded in 2017, YouiBot Robotics, based in Shenzhen, China, was already developing autonomous robots when the COVID-19 outbreak occurred. However, the technology was quickly adapted to transform them into disinfection devices and has already been deployed in factories, offices, an airport and a hospital in Wuhan. During the day, the robot uses thermal cameras to accurately monitor the body temperature of crowds of people, and UVC light is used to efficiently disinfect at night.

UVD Robot

Danish startup UVD Robot has been experiencing a huge demand for their fully autonomous UV disinfection robots from Italy and China. Founded in 2016 by Blue Ocean Robotics, the UVD Robot has a reputation for its highly effective and unique technology, the result of a 6-year intensive R&D effort. It was originally developed to combat the cost of hospital infections by filling a gap for additional cleaning and disinfection measures. Not only is the UVD Robot system a validated and efficient disinfection process that ensures a very safe environment, but because it is autonomous, it can enter critical rooms to disinfect high-touch surfaces and the air, making it quickly available for the next patient.

The effectiveness of the robot is being tested at Ziekenhuis Geel hospital in Belgium as of April 2020.

Dimer UVC Innovations

Commercial airlines play a direct role in the way diseases spread around the globe. As a result of the novel coronavirus pandemic, there will soon be regulations or standards for airlines in regards to onboard hygiene, in addition to adjusted seating solutions. The GermFalcon robot, developed by Dimer UVC Innovations, was specifically created to improve airplane hygiene using UVC light to deactivate viruses, bacteria and superbugs on surfaces and surrounding air. Designed to navigate an airplane cabin, it has strategically placed UVC lamps that can expose all high-touch surfaces to the UVC light. This germ-killing system, although currently human-operated, is a fast and effective response to COVID-19.

The Research & Development Tax Credit

Enacted in 1981, the now permanent Federal Research and Development (R&D) Tax Credit allows a credit that typically ranges from 4%-7% of eligible spending for new and improved products and processes. Qualified research must meet the following four criteria:

- Must be technological in nature

- Must be a component of the taxpayer’s business

- Must represent R&D in the experimental sense and generally includes all such costs related to the development or improvement of a product or process

- Must eliminate uncertainty through a process of experimentation that considers one or more alternatives

Eligible costs include US employee wages, cost of supplies consumed in the R&D process, cost of pre-production testing, US contract research expenses, and certain costs associated with developing a patent.

On December 18, 2015, President Obama signed the PATH Act, making the R&D Tax Credit permanent. Beginning in 2016, the R&D credit has been used to offset Alternative Minimum Tax for companies with revenue below $50MM, and startup businesses can obtain up to $250,000 per year in cash rebates applied directly toward payroll taxes.

Conclusion

Utilizing 3D printing methodologies to design and manufacture UVC disinfectant robots can be extremely beneficial to companies in terms of meeting customer demand during the coronavirus pandemic. Already, companies are leveraging this technology to create and test both internal and external robotic components, as well as reduce production and assembly time.

UVC disinfectant robots may be crucial to reducing the spread of COVID-19 and prevent the spread of germs, and the sooner they are readily available on the market, the better. Companies that are utilizing 3D printing during the design, development or final production of UVC disinfectant robots are entitled to state and federal R&D tax credits.